A New Foundation for Advanced Manufacturing

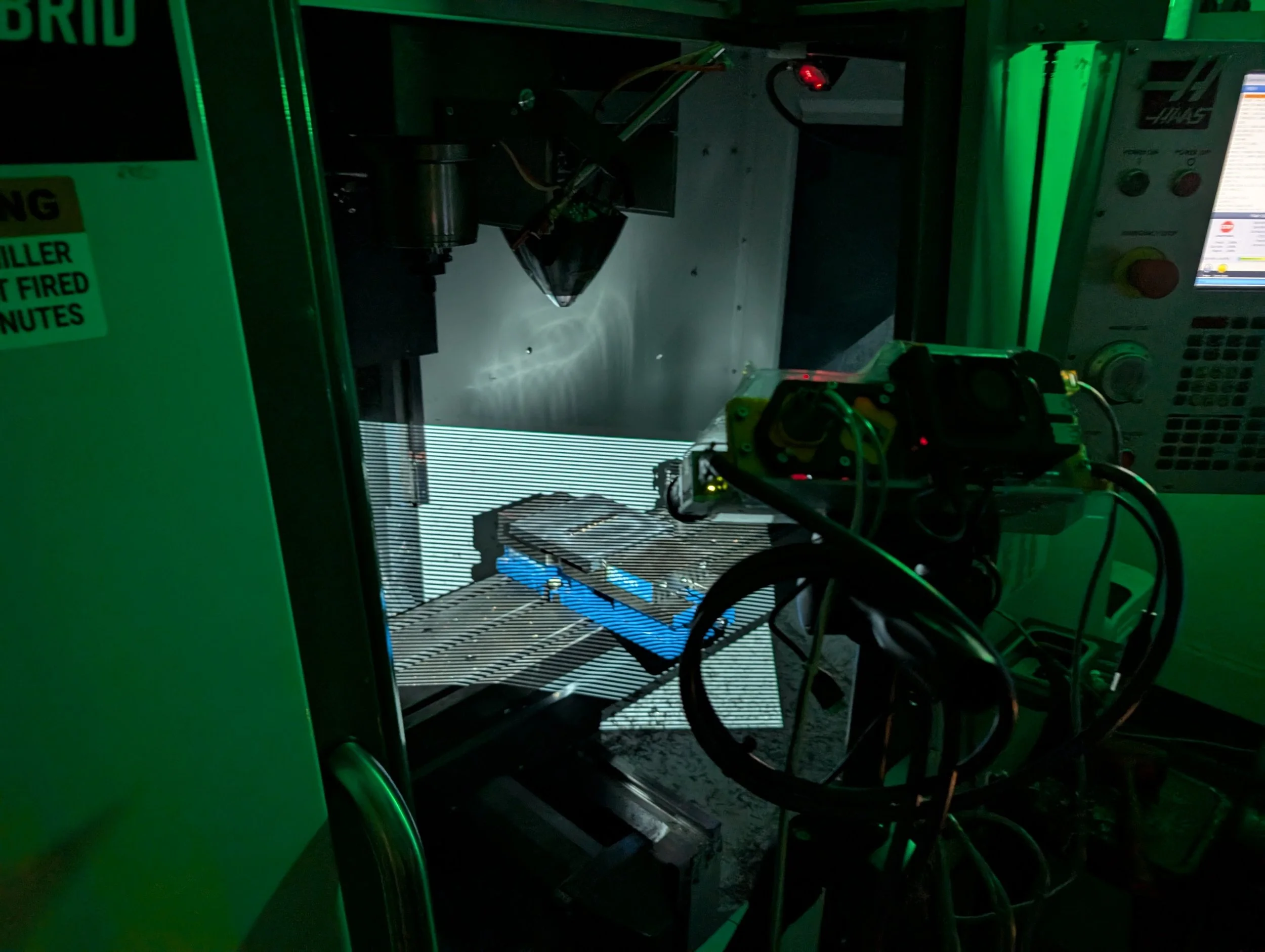

At MatterField Manufacturing, we’re building tools to solve complex manufacturing problems. Our solution, Amos, is an operating system for advanced manufacturing tools.

Amos combines high-precision, live in-situ monitoring with real-time data processing to deliver actionable process insights in almost any additive or hybrid manufacturing process.

Reduce the burden on your machine operators, detect defects in real time, and understand the complete state of your part. All done fully locally and without sending any proprietary information offsite.

MatterField and Amos can help you unlock the potential of advanced manufacturing tools for the most complex applications.

MatterField delivers real-time insight into advanced manufacturing—by unifying high-fidelity geometry with in-situ sensing, right at the source.

Because our entire software and hardware stack is designed as a single system, data flows seamlessly from sensor to geometry to process insight, without the complexity or fragility of vendor integrations.

This isn’t just a vision—it’s already running on real manufacturing equipment. We’ve installed Amos on more than half a dozen additive and hybrid manufacturing systems, where it processes hundreds of thousands of data points per second using secure, on-premise edge computing. No cloud uploads, no external processing—just high-speed, local analysis that keeps proprietary data safe and your process in control. Whether you're tracking deposition in real time, identifying defects before they propagate, or validating geometry before finishing, MatterField gives you a precise, trusted view of part state—every step of the way.